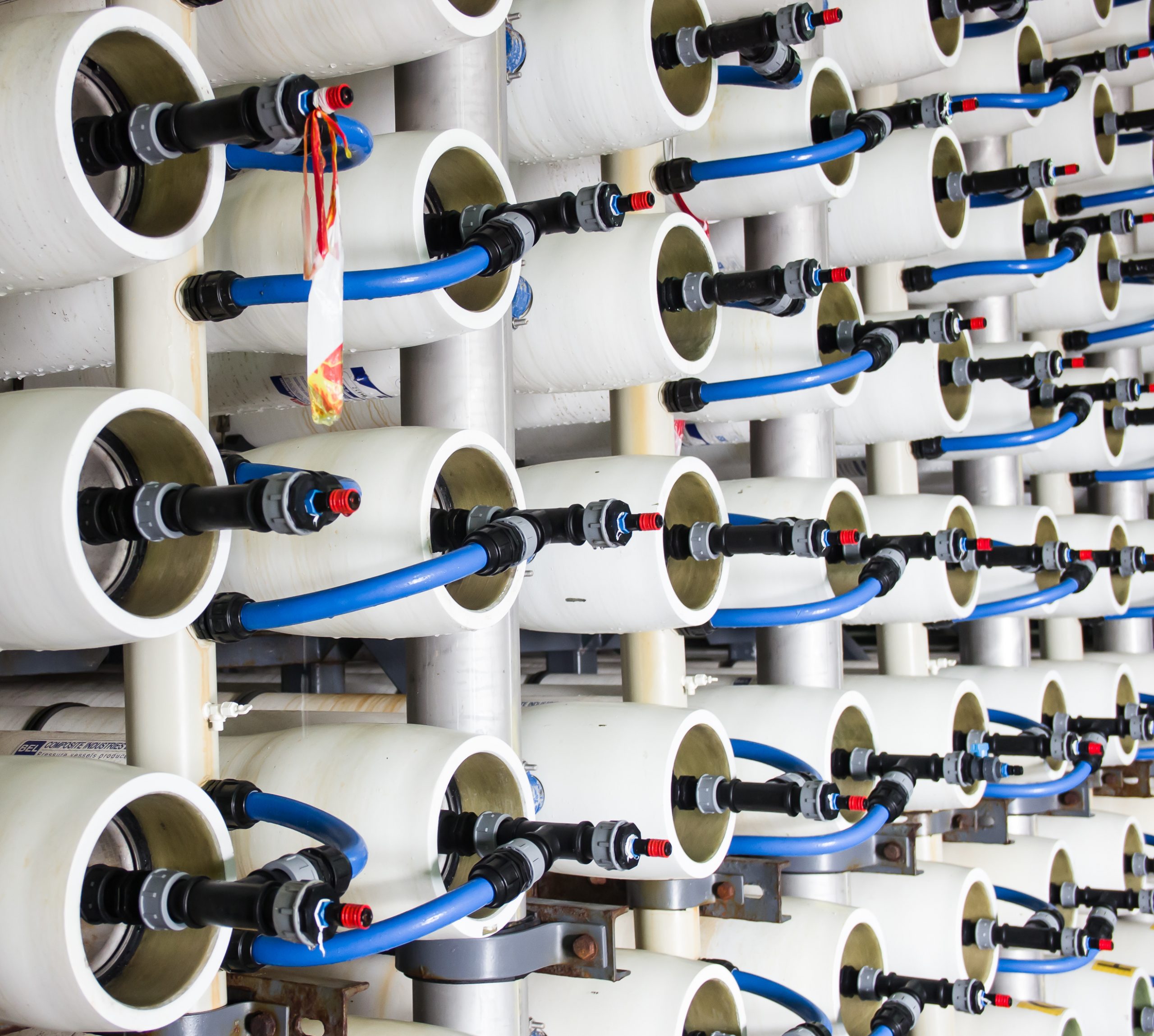

Membrane treatment plant survey

Operating membranes at maximum potential

To run a membrane water treatment plant to to maximum performance takes the right treatment program, high quality equipment and excellence in operation. At WaterIQ we help maximise your water treatment by providing an comprehensive and expert assessment of the whole of your water treatment plant. Giving you the right information to solve the right problems.

We work with you and our industry partner Membrane Works you to perform a detailed survey of your plant. The survey gives you a starting point: what’s working efficiently? What’s not? Are there areas of the plant that are not following industry best practices? What’s the most cost-effective treatments? How can you better meet your operational objectives?

The assessment includes:

- Identifying operational goals and performance gaps

- Historical operational review and failure analysis

- Water quality sampling and testing

- Performance modelling

- Chemical treatment program review

- Maintenance and operational review

- Plant inspection and assessment

Independent

- Independent results you can trust

- No affiliations with specific vendors or products

Comprehensive

- Water quality testing

- Membrane performance modelling and benchmarking

- Maintenance and Operational review

- Equipment and plant inspection

Expert

- Experience scientists and engineers with broad based industry experiences

- Works class modelling and performance software

Benefits

- Maximize water production

- Reduce treatment and maintenance cost

- Solve operational issues

Goals

Understanding what YOUR objectives are is critical to creating a program that will deliver. We start with documenting performance history and improvement goals to make an actionable plan.

Inspect

Our experts will come to your site and conduct a detailed inspection of your membrane plant including all chemical, operational and mechanical aspects.

Optimize

System optimization using modelling software and industry benchmarking will be conducted to identify gaps and where performance enhancements may be gained.

Action

A detailed report with clear and deliverable actions is produced and we work with you in developing an action plan with various stakeholders.

Maintain The Gain

We understand the competing objectives that divide everybody's time. Thus, we pride a detailed follow up review to help support implementation and overcome barriers that may have blocked progress.

Why do we need a system audit?

Water treatment is not just a mechanical process. Many parts come together to help maximize performance including the maintenance of equipment, operational procedures and responses to changes, the treatment chemicals, changes in feed water, pre-treatment system and service regime. By its very nature all these systems have different responsible parties, thus a formalized system audit makes sure that you’re getting the full picture of your plant performance and helps align the different stakeholders to making improvements.

What is involved in the site inspection?

The site inspection takes a number of steps:

- Establishing operational goals, known performance gaps and involved team

- Review of P&ID and operational data

- Inspection of plant equipment

- Interviews with maintenance, operations and engineering teams

- Maintenance review and understanding of historical problems

- Water sampling and off-site water quality testing including treatment verification

Why choose WaterIQ?

WaterIQ combines a unique mix of local and global experiences coupled with a strong scientific background and commercial expertise in its consulting services. This allows us to bring you insights that can truly be called Smart Water Solutions